Galvanizing Flux:– A prevention is better than corrosion!

Prime Specialities ( ISO 9001:2015 ) started in 1994 in Hyderabad. Since 1994, we have been manufacturing fine chemicals, specialty chemicals, and pharmaceuticals to meet the needs of customers in various industries. At the age of 20, we are a growing company specializing in water and metal treatment solutions. The PROCARE series offers reverse osmosis membrane maintenance chemicals. These are industry standards and the best RO maintenance and care products. Our ROTO specialty chemicals are well known and recognized by users of large corporations and multinational corporations.

We have understood the needs of our customers and applications, developed solutions, and provide products that meet our requirements. Our products may not fully meet the requirements and will significantly improve operating conditions and equipment life. Quality is our passion and will continue to be the driving force for our future growth. We always provide high-quality products and solutions.

- Our mission:

- To consistently create new chemical products using the latest technology.

- Focus on clear customer choices

- Our vision:

- To be a globally recognized chemical manufacturing company.

- Apply the best eco-friendly technology.

- Improve your core competence through continuous product improvements.

- Our Value:

- Honesty Our team maintains professionalism and integrity in every activity.

- Customer satisfaction is important.

This ensures continuous improvement in quality and process, and customer satisfaction through top-quality products and on-time delivery.

From the beginning, the company has focused on providing the highest levels of customer satisfaction by providing the best selection of welding materials + equipment, power tools, and occupational safety products. Our showroom is located in the heart of customers, where all the products used in the manufacturing/manufacturing industry are on display.

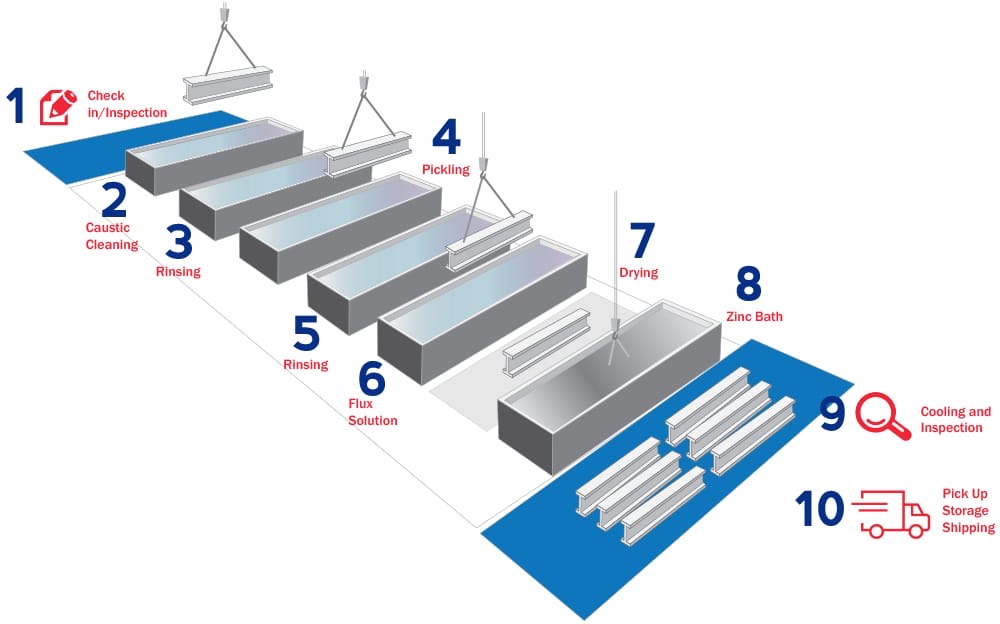

Protecting structural steel with galvanization provides important measurable benefits: –

- Minimum Acquisition Cost: – Galvanization has a lower initial cost than many other commonly designated steel protective coatings. (The cost of applying labor-intensive coatings such as painting is much higher than the cost of operating a factory such as galvanizing.)

- Reduced maintenance / minimized long-term costs: – Even if the initial cost of galvanizing is higher than the alternative coating, galvanizing is often the cheapest in the long run (because it lasts longer and requires less maintenance). Also, if the building is remote, or if it involves a plant shutdown or production interruption, maintenance can cause problems and increase costs.

- Long service life: – Life expectancy of electroplated coatings on typical components is well over 50 years in most rural environments and over 20-25 years in heavy urban and coastal environments.

- Reliability. Galvanization complies with Australian / New Zealand standard 4680 and the standard minimum coating thickness applies. The life and performance of the coating is reliable and predictable.

- Hardest coating. The galvanized coating has a unique metallurgical construction that provides excellent resistance to mechanical damage during transportation, assembly, and service.

- Automatic damage protection: – The electroplated coating preferentially corrodes the steel and provides cathodic protection or sacrificial protection for small areas of steel exposed to damage. Unlike organic coatings, there is no need to repair small damaged areas.

Performance in a variety of environments: –

The excellent corrosion resistance of zinc oxide coatings in air, soil, concrete, and most natural waters depends on insoluble zinc oxide, hydroxides, carbonates, and the environment. Basic zinc salt. When the patina is stable, the reaction between the coating and its environment proceeds at a significantly reduced rate, extending the life of the coating.

Lifecycle & Cost for Galvanized: –

Two of the most important considerations when choosing an anticorrosion coating system are the time to the maintenance required and the cost of coating. The durability of the coating system can be estimated using Australian standards after assessing the corrosiveness of the environment, allowing the user to know when maintenance costs will begin.

The cost aspect of Coatings is typically divided into two areas: initial cost and maintenance cost. The life cycle cost of a coating combines the total acquisition cost and the maintenance cost to calculate the total cost of the coating while the steel is in use.

Due to interest rates and inflation, the value of money rarely becomes constant over time. Lifecycle cost explains this by converting all future costs into the present value, that is, the cost of today’s value. Galvanization has a very long service life in most environments and often requires no maintenance throughout the life of the project. This makes galvanization as a protective coating an unrivaled price/performance ratio.

Aso check our other product: Inhibitedglycol

Website: https://galvanizingflux.com/

Call: +91- 96184 00511, 040– 40055050, 40202121

Mail: web@primespl.com